CARRIAGE STOP for Mini Lathe withCalibrated U. S. And Metric Dials

Designed To Fit Primarily the MX-210V Mini Lathe. This device is used to control the travel distance between the Carriage and the Chuck.

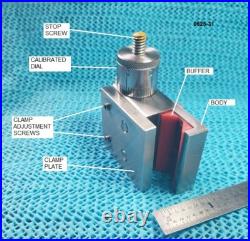

When facing or boring the work piece, the stop will provide repeatable stop reference cut after cut. The calibrations on the dial allow for accurate steps to be cut along the X axis. Calibrated stop is machined of Steel and uses a ¼ - 20 Stainless Steel screw to offer the accuracy that you can rely on. Every full turn of the calibrated dial is equal to 0.050 travel. The dial is calibrated every 0.001. This may be more accuracy than you require, but it is there if you need it. The METRIC calibrated stop uses a M8 - 1. The ways on these mini lathes are not hard enough to avoid abrasions. To help protect your machine, a 3D printed plastic buffer is provided to avert wear to the upper surface of the bed.The long STOP SCREW (threaded rod) provides approximately 1 inch of calibrated travel. I designed this device to provide an accurate depth of cut across the X axis on my Mini Lathe.

I have had requests to manufacture stops for a few other machines and has turned into a sort of hobby project. It takes approximately 9-10 hours to manufacture each one. As a semi-retired Mold Maker it provides something for me to do and you can expect a product that actually works. The device is easily mounted to the lathe.By tightening or loosening the two. 1/4-20 screws located on the top surface. The stop can be moved and secured along the travel of the bed way.

A separate lock screw is part of the design to keep the dial in position. The dial is easily adjusted by just loosening that lock screw.

Finger tight is well enough. The adjustment is very simple, by rotating the dial, the length of the protruding screw is extended or withdrawn. The dial is calibrated with 50 lines. Each line is equal to. The simple design allows for times when you need to briefly move the travel of compound closer to the chuck and then go right back to your original stop position. This can be easily done by loosening the lock dial screw an extra 1 - 2 turns and the dial and threaded shaft pulls out of the main block. Then it can be placed back into main block and you can go right back to your stop setting. Many rely on the compound to accomplish that task. However, the compound may be on a slight angle which would change the depth of cut across the X axis. SAFETY ALERT : When making any adjustments to the dial or locking screws, the lathe chuck should be at full stop.Serious, even catastrophic injuries can occur to the operator when the chuck is spinning. Material: Main Body - Hot Rolled Steel. Adjustment Screw - Stainless Steel. Dial - Cold Drawn Steel.

Dimensions: H - 1.00" X W - 2.25" X L - 2.25 Measurements are approx. N inches Dial 2 20. Screw: Allows 1.00" of adjustment range (1/4-20 x 2.5" Length).

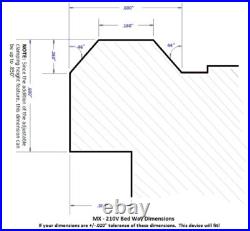

Please check the images attached to the listing as there is dimensional drawing of the bed way that this carriage stop is designed to fit. However, the clamping design has adjustment screws to allow for a taller bed way profile. MX -210V 8X16 Mini Lathe.MX -600A 8.7X29.5 Mini Lathe. MX -600B 8.7X23.6 Mini Lathe. MX -750 8.7X23.6 Mini Lathe. The carriage stop was created to fit the MX 210 V Mini-Lathe. The mini lathes listed are verified as I have made stops for a few of them.

This device will fit many other mini lathes as the bed ways for most of the mini lathes manufactured in China are of the same design and dimension. This model (V4) is an updated version that has two set screws in the Clamp Plate that provides a wide range of adjustability to the clamping height allowing it to fit more than the MX-210V. UPGRADES: THIS UPGRADE IS INCLUDED WITH THE SALE. For an additional charge, I also offer an extra screw and dial that is calibrated in metric. If you have a need to switch between an inch and metric device.The Adjustment Screw and Dial is interchangeable. It is a simple conversion as the dial and screw are the only components which need to be swapped out in the Main Body.

Every full rotation of the dial is equal to 1 mm. Increments on the dial is equal to.The total extended range of the screw is 45mm. A Full Metric version Carriage Stop, is available. Please contact me if you are interested in any upgrade or have any questions about manufacturing a custom Carriage Stop that will fit your machine.

I also sell two other standard model Carriage Stops which fit the ATLAS. The design is based on my concept and is being improved constantly. There are a good amount of hours involved in the manufacturing of the Carriage Stops.

Should you require a Carriage Stop which will fit another lathe? I can manufacture a Custom Carriage Stop that will fit your Lathe based on the same design.Thank you for checking out my listing.