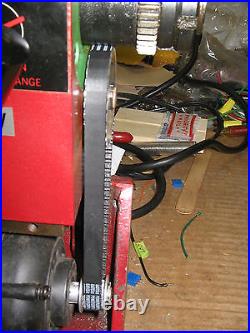

Asian Mini Metal Lathe 7 x 10,12, & 14 Gear/Belt Power Upgrade 31 Reduction

Ready to install, No modification required. This kit fits machines that have 8mmThat's Nominal. 314 motor shaft and 10mmThat's Nominal. Search --- tek413 --- for installation vid. Fits Asian Mini Lathe 7" x 10", 12", & 14", Pulley/Belt Reduction Power UpGrade, Aluminum XL Pulleys & Belt, 3 to 1 Reduction instead of the OEM 1.82 to 1, 40% Power increase, Ideal for spinning those 4 & 5 Inch Chucks.

This upgrade lowers Max RPM in Low Gear to Approx. 700 RPM, and 1600 RPM in High Gear. This Upgrade Kit fits machines with (small gear) 8mm motor shaft bore w/3mm Key, (large gear) 10mm intermediate shaft bore w/ 4mm Key. Brief Background, the belt reduction system on the Mini Lathe consist of a Timing belt a Flanged motor & (Un-flanged Intermediate Timing pulley and for Good Reason) Firstly only one pulley with dual flanges for Belt Guidance is require, if the intermediate pulley had Flanges you couldn't determine proper Parallel tracking of the Belt, You Just Can't Short Cut the Belt Tracking, Proper Tracking is a Must for Belt life, ------------ ("You can't just install it and forget it"), ------------- the small pulley is chosen as the guidance pulley because there is Less Drag from belt edge contact than there would be with a Flanged Large pulley, My kits don't have Flanges on the Intermediate Pulleys, instead I try to show Folks really how easy the belt alignment is while Maintaining as much Power as Possible, and we all know how important that is for the Mini Lathe.The tips here in are based on the people who have contacted me, asking how the heck do I align this, the belt alignment is easy on Machines that have the rolling/pivoting motor mounts, the mount I'm illustrating here is Push/Pull Stud Type, First one of the Biggest Errors people make is in not considering the Push Studs, they see that the Motor is Bolted in with Pull Studs and remove the Nuts to remove the Motor thinking that they will leave the Push Studs Locked in position and this will make the process EASY, !!! The Push Studs need to be Backed off Completely from contact with the Motor when you start your re- installation, Basically after you have your Pulleys installed and Belt in position you Hand tighten the Pull Stud Nuts with the Motor Level(Parallel to the Bed Frame) then Kiss the Push Studs by hand to the Motor. Then tighten the top Push Stud with a wrench a Little, you'll notice that the belt is starting to tighten, then tighten the Bottom Push Stud a little, turn the Spindle back and forth in Low Gear and check the belt Tracking, Is it running about center of the intermediate pulley, If not and the belt is trying to run Right toward the timing cover, "Your Motors' Brush Side is Too Low" If the belt is trying to run Left Toward the Headstock, "Your Motors' Pulley side is Too Low", That's really all there is to it, just remember what the Push Studs are doing, they serve to tighten the tension of the Belt as well as tighten the Motor to the Bed Casting.

I've included about (10 photos "3 thru 12"), one "Photo 7" Shows where my first try the Motor was Low on the Brush Side, on my second try I got it near Perfect, also it's not unusual & normal for a belt to track a half millimeter left in forward or the same to the right in Reverse. Happy Machining, Thanks for looking, Questions and Comments are welcome. Asian Mini Metal Lathe 7 x 10,12, & 14 Gear/Belt Power Upgrade 3:1 Reduction.