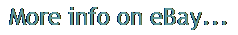

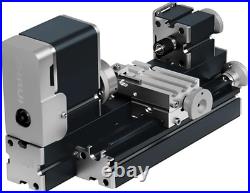

All-Metal Miniature Lathe 36W 20000Rpm Didactical Mini Metal Lathe Machine for H

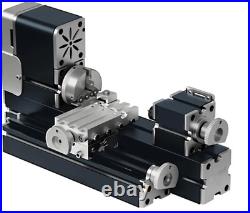

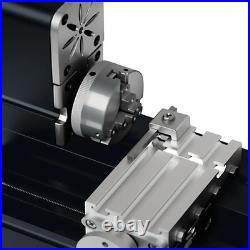

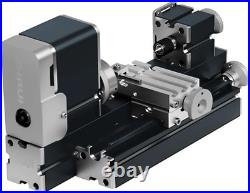

All-metal Miniature Lathe 36W 20000rpm Didactical Mini metal Lathe Machine for Hobbyist Woodworking Craft. Hi-power motor is adopted with all drive axes, maximum speed up to 20,000 rpm;Input voltage/Current /Power: 12V/3A /36W;Input Voltage of Switch Power Supply: 110V-240V. The largest diameter of processed material: 50mm Positive Jaw Gripping Range: 3mm-30mm, Opposite Jaw Gripping Range: 3mm-50mm;Kind Notice: manual measurement, there will be 2-3mm error. The length of processed material: 150mm;The chuck and collets is 1 to 6mm;X-axis slider travels:150mm;Machine size:310mm100mm150mm;Bottom plate size: 315mm200mm17mm.

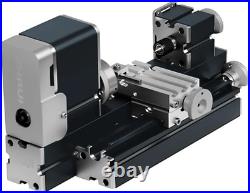

The processed materials can be clamped by three-jaw chuck / collets, its maximum diameter is 50mm, center height-25mm, center distance- 150 mm. The motor case and headstock of all-metal machine tools is jointed completely. Main parts configure with metal structure and no plastic components in the whole machine body, such as motor box, headstock, hand wheels, slider, 3-jaw chunk/4-jaw chunk, turning tools clamping jaw, machine bed, gear, side cover, working table, connection piece, tailstock, countershaft, drive belt cover etc. Fan built-in motor is featured with ultra-quiet & high rotary speed.

That's special customized option for motor cooling & effective work. The most parts of machine tools are dealt with two surface treatment methods of electroplating and ink-jet anodized to make appearance more cleaning & glorious, lasting rust-proof. Machine bed is made of Europe standard T-type aluminum material, moving more precisely &smoothly.